Agate stripping guides are essential tools used in knife making to maintain blade precision. They ensure proper spacing and alignment, enhancing overall craftsmanship and efficiency in the process.

1.1 What Are Agate Stripping Guides?

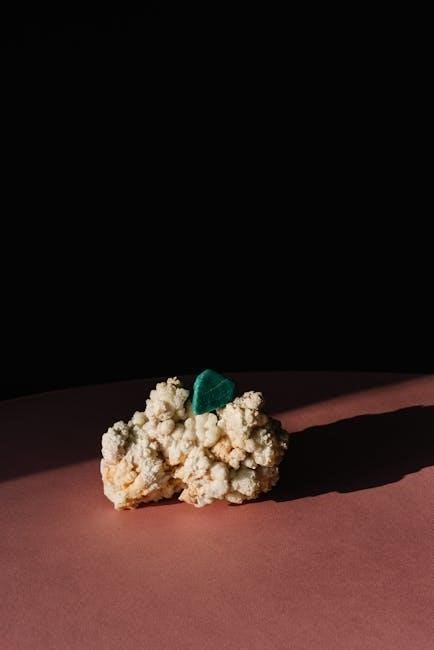

Agate stripping guides are specialized tools, typically made from high-quality agate stone, used to remove metal shavings during knife making. Their smooth, non-porous surface ensures efficient stripping without damaging the blade. Durable and precise, they are favored for their ability to maintain sharp edges and prevent metal buildup, making them indispensable in crafting precise, professional-grade knives.

1.2 Importance in Various Industries

Agate stripping guides are crucial beyond knife making, serving industries like metalworking, jewelry crafting, and precision engineering. Their ability to maintain sharp edges and prevent metal buildup makes them invaluable for intricate tasks. These tools enhance efficiency and accuracy, ensuring high-quality finishes in professional-grade products, making them indispensable across various manufacturing and artisanal sectors.

History and Evolution

Agate stripping guides trace their origins to ancient craftsmanship, initially used in knife making for their hardness and precision. Over time, their design evolved, incorporating modern materials while retaining traditional functionality.

2.1 Origins and Historical Use

Agate stripping guides have ancient roots, valued for their durability and smooth surface. Historically, agate was used in knife making and similar crafts due to its natural hardness, ensuring precise cuts and alignments. Its use dates back to early toolmaking, where artisans prized agate for its ability to maintain sharp edges and resist wear, making it integral to precise craftsmanship.

2.2 Modern Advancements

Modern advancements in agate stripping guides include the integration of synthetic materials and advanced manufacturing techniques. Laser-cut designs and precision engineering have enhanced accuracy and durability. These innovations ensure smoother operations and consistent results, making agate guides indispensable in contemporary craftsmanship and industrial applications.

Materials and Tools Needed

Essential materials include high-quality agate stones, synthetic alternatives, and durable adhesives. Tools like drills, abrasive wheels, and precision cutters are crucial for accurate stripping processes and safety.

3.1 Essential Tools for the Process

Drills, abrasive wheels, and precision cutters are vital for agate stripping. Safety gear like gloves and goggles is crucial. Sharpened tools ensure efficiency, while proper alignment devices protect the agate surface from damage during stripping.

3.2 Recommended Materials for Optimal Results

High-quality agate is essential for durability and precision. Non-porous materials prevent contamination, while specialized adhesives ensure secure bonding. Using aligned spacers and polished surfaces minimizes damage during stripping, ensuring smooth and consistent results. Proper material selection enhances both efficiency and the final product’s quality.

Step-by-Step Guide to Agate Stripping

Start by preparing the agate, then align the guide. Carefully strip the material, maintaining consistent pressure. Repeat as needed and finish by drilling for final adjustments.

4.1 Preparing the Workspace

Begin by ensuring a clean, stable workbench. Gather all necessary tools and materials within easy reach. Proper lighting is essential for visibility. Wear protective gear, including gloves and safety goggles. A well-ventilated area is crucial to avoid inhaling dust. Secure the agate firmly in a vice to maintain control during the stripping process. Organize your workspace to minimize distractions and ensure efficiency.

4.2 Executing the Stripping Process

Begin with coarse-grit sandpaper to remove surface imperfections, gradually progressing to finer grits for polishing. Maintain consistent, controlled pressure to avoid uneven stripping. Use the agate stripping guide to ensure precise alignment and uniformity. Regularly inspect the agate to monitor progress and adjust techniques as needed to achieve the desired finish. This method ensures efficiency and precision throughout the process.

Safety Precautions and Best Practices

Always wear personal protective equipment, including gloves and safety glasses, to prevent injuries. Ensure proper ventilation and maintain a clean workspace to avoid hazards and ensure optimal results.

5.1 Personal Protective Equipment

Wear gloves to prevent hand injuries and ensure a firm grip on tools. Safety glasses protect eyes from debris. Use a dust mask to avoid inhaling particles during stripping. Steel-toe boots safeguard feet from heavy equipment or falling objects, ensuring overall safety and comfort during the process. Proper PPE enhances focus and reduces workplace hazards.

5.2 Workspace Safety Measures

Ensure the workspace is well-ventilated to prevent dust accumulation and maintain visibility. Secure tools and materials firmly to prevent unexpected movement. Keep flammable materials away from heat sources. Regularly inspect equipment for wear and tear. Store sharp objects safely when not in use. Maintain a clean, organized workspace to minimize accidents and ensure efficient workflow during the stripping process.

Tips for Effective Agate Stripping

Use high-quality tools to prevent damage. Maintain consistent pressure and alignment. Regularly inspect and sharpen tools for optimal results. Handle agate with care to avoid chipping or breaking.

6.1 Choosing the Right Tools

Selecting the right tools is crucial for effective agate stripping. Opt for tools made from durable, high-quality materials that can withstand the hardness of agate. Ensure your tools have precise edges to maintain control and avoid damage. Regularly sharpen and maintain tools to ensure optimal performance and achieve desired results efficiently.

6.2 Maintaining Control and Precision

Maintaining control and precision is vital for successful agate stripping. Use steady, deliberate movements and ensure tools are held at the correct angle. Apply consistent, even pressure to avoid uneven stripping. Proper workspace setup and lighting can enhance visibility, allowing for greater accuracy. Utilize guides or templates to help maintain consistent results and achieve the desired finish.

Common Mistakes and How to Avoid Them

Common mistakes include tool wear, surface damage, and uneven pressure. Proper tool maintenance, surface protection, and controlled pressure help avoid these issues effectively.

7.1 Avoiding Damage to Agate Surfaces

To prevent damage to agate surfaces, use diamond-coated files or silicon carbide stones, as they are designed for such materials. Apply light, consistent pressure to avoid scratching or cracking. Regularly clean the surface to remove debris, which can cause abrasion. Using a soft, dry cloth to wipe down the agate ensures it remains intact and functional throughout the stripping process.

7.2 Preventing Tool Wear and Tear

Regularly clean and maintain tools to prevent residue buildup. Store them in a dry, protected environment to avoid rust or damage. Sharpen tools when necessary to maintain efficiency and reduce wear. Use the correct tool for each task to avoid excessive strain. Proper care ensures longevity and optimal performance of your agate stripping guides.

Advanced Techniques in Agate Stripping

Exploring precision techniques, specialized stripping methods, and integrating modern technology can elevate your agate stripping process. These advanced approaches enhance efficiency and result quality significantly.

8.1 Specialized Stripping Methods

Specialized stripping methods involve precision techniques like controlled pressure application and angled stripping. These methods minimize material loss and ensure smooth surfaces. Advanced tools, such as diamond-coated files, are often used for intricate patterns. Additionally, incorporating modern technology, like CNC machines, can enhance accuracy and consistency in the stripping process, making it more efficient and precise for complex designs.

8.2 Incorporating Modern Technology

Modern technology enhances agate stripping efficiency through advanced tools like CNC machines and laser-guided systems. These innovations enable precise measurements and uniform stripping. Automation reduces manual labor, while software aids in real-time monitoring and customization. Such technological integration ensures higher accuracy, faster processing, and superior finish quality, making agate stripping guides more versatile and effective in contemporary applications.

Maintenance and Aftercare of Stripping Guides

Regular cleaning with mild detergents and soft cloths prevents residue buildup. Store guides in a dry, cool place to avoid damage. Inspect them periodically for wear.

9.1 Cleaning and Storage Practices

Agate stripping guides should be cleaned with mild detergents and soft cloths to avoid scratching. Rinse thoroughly and dry to prevent water spots. Store in a dry, cool place, away from direct sunlight, to maintain their integrity. Use protective cases or pouches to safeguard against dust and accidental damage, ensuring longevity and optimal performance.

9.2 Regular Inspection and Replacement

Regular inspection of agate stripping guides is crucial to ensure optimal performance. Check for signs of wear, such as scratches or chips, which can affect precision. Replace guides when they show significant damage to maintain accuracy and prevent further issues. Schedule inspections after heavy use or as part of routine maintenance to prolong their lifespan and reliability.

Applications of Agate Stripping Guides

Agate stripping guides are versatile tools, widely used in knife making and other precision crafts. Their durability and smooth surface make them ideal for various industrial and artisanal applications.

10.1 Use in Knife Making

Agate stripping guides are indispensable in knife making, ensuring precise blade alignment and spacing during assembly. Their smooth, non-porous surface prevents damage to the knife components, making them ideal for maintaining professionalism and craftsmanship. These guides are highly durable and preferred by both professional knife makers and hobbyists for achieving consistent, high-quality results in their work.

10.2 Applications in Other Industries

Agate stripping guides are versatile tools with applications beyond knife making. They are used in jewelry making, watchmaking, and even art restoration for their smooth, non-porous surface. Their precision and durability make them ideal for tasks requiring delicate handling and alignment, ensuring protection of sensitive materials and promoting professional results across various creative and technical industries.

Troubleshooting Common Issues

Identifying and resolving issues with agate stripping guides often involves addressing misalignment or damage. Explore common problems and practical solutions to ensure optimal performance and longevity.

11.1 Diagnosing Problems

Diagnosing issues with agate stripping guides involves identifying misalignment, wear, or damage. Inspect for uneven wear, cracks, or improper seating. Use magnifying tools to spot surface damage. Check tool calibration and blade alignment. Test functionality by running a trial strip. Addressing problems early prevents further damage and ensures consistent results. Regular inspection is key to maintaining guide efficiency and accuracy in knife making processes.

11.2 Effective Solutions

Effective solutions for agate stripping guide issues involve recalibrating tools, ensuring proper alignment, and cleaning surfaces. Polishing compounds can restore guide integrity, while replacing worn parts prevents further damage. Regular maintenance, such as lubricating moving components, enhances durability. Addressing problems promptly with the right techniques ensures optimal performance and extends the lifespan of the guides, maintaining precision in knife making and other applications.

Agate stripping guides are versatile tools enhancing precision in knife making and beyond. Proper care and maintenance ensure longevity, making them indispensable for craftsmen and industries alike.

12.1 Summary of Key Points

Agate stripping guides are versatile tools with historical origins, offering precision in knife making and other industries. They require proper materials and maintenance to ensure efficiency. Safety measures and best practices are crucial for effective use. By following expert tips and avoiding common mistakes, users can maximize their benefits. These guides remain essential for craftsmen seeking accuracy and durability in their work.

12.2 Future Prospects

Agate stripping guides are poised for growth with advancements in technology and material science. Innovations like nanotechnology and eco-friendly practices may enhance their durability and sustainability. As industries evolve, these guides could see expanded applications beyond knife making, offering precise solutions for various precision-crafting sectors. Their timeless utility ensures continued relevance in modern manufacturing and craftsmanship.

Leave a Reply

You must be logged in to post a comment.